Water is essential in mining for mineral extraction, dust control, and refining. Poor water management can cause contamination, regulatory fines, and operational inefficiencies. Water operators play a critical role in maintaining quality, compliance, and sustainability, but traditional methods like manual testing and routine maintenance are prone to errors and delays.

With stricter regulations and growing environmental concerns, mining companies need smarter solutions. Automated water monitoring provides real-time data and predictive insights,

The Core Responsibilities of Water Operators in Mining

Mining operations depend on water for essential processes, including mineral extraction, dust suppression, refining, and waste management. Poor water management can result in environmental damage, regulatory penalties, and inefficiencies that disrupt operations. Water operators play a vital role in preventing these risks.

Their responsibilities extend beyond monitoring water quality. They must also ensure compliance with environmental regulations, maintain treatment systems, and respond swiftly to spills or contamination incidents. As mining operations become more complex, water operators need manual and automated water management expertise to maintain efficiency and sustainability.

To meet these demands, water operators are responsible for a range of key tasks, including:

- Conducting water sampling to detect contaminants like heavy metals, nitrates, and turbidity.

- Managing filtration, sedimentation, and chemical treatments to maintain water quality.

- Ensuring compliance with wastewater discharge, recycling, and conservation regulations.

- Inspecting and repairing pumps, pipelines, storage tanks, and filtration systems.

- Recording and analyzing water quality data to identify risks and improve processes.

- Responding to spills, leaks, and contamination to minimize environmental impact.

Water operators are indispensable in ensuring that mining operations remain efficient, compliant, and sustainable, making them a key component of the industry’s long-term success.

Water Quality Control in Mining Operations

Water quality control is one of the most critical responsibilities in mining operations. The quality of water used and discharged directly impacts environmental sustainability, regulatory compliance, and operational efficiency. Poor water management can lead to heavy fines, legal liabilities, and irreversible damage to local water sources, affecting wildlife and surrounding communities.

Water operators must continuously monitor and control key water quality parameters to prevent these risks. This process ensures that water remains safe for use in mining activities, meets regulatory discharge standards, and supports efficient treatment processes. Below are the essential parameters that water operators must monitor:

| Parameter | Role in Mining Operations |

| pH Levels | Prevents equipment corrosion and ensures safe chemical treatment. |

| Dissolved Oxygen | Reduces bacterial growth and supports discharged water quality. |

| Turbidity & Solids | Prevents clogging and maintains filtration efficiency. |

| Heavy Metals | Prevents toxic contamination of water sources. |

| Conductivity | Measures dissolved salts to determine water usability. |

Failure to manage water quality effectively increases contamination risks, leads to costly remediation, and exposes mining companies to regulatory penalties.

Regulatory Requirements for Mining Water Operators

Mining water operators must comply with strict environmental and safety regulations to prevent pollution, ensure water sustainability, and protect public health. Regulatory bodies enforce laws that govern water usage, treatment, and disposal, requiring operators to implement stringent monitoring and reporting practices.

Non-compliance can lead to significant consequences, including financial penalties, operational shutdowns, and reputational damage. Below are key regulatory bodies and their roles in mining water management:

| Regulatory Body | Role in Mining Water Management |

| Environmental Protection Agency (EPA) | Regulates wastewater discharge limits and enforces water quality monitoring protocols. |

| Mine Safety and Health Administration (MSHA) | Oversees safe water usage to protect worker health and safety in mining operations. |

| National Pollutant Discharge Elimination System (NPDES) | Requires permits and monitoring for wastewater discharges to prevent contamination. |

| State and Local Regulations | Sets additional rules for water usage, treatment, and disposal based on regional requirements. |

Ignoring these regulations increases the risk of compliance violations, costly legal actions, and operational disruptions, making proper water management a top priority for mining companies.

Challenges in Mining Water Management

Water management in mining presents several challenges that impact efficiency, compliance, and sustainability. Issues such as water scarcity, contamination risks, and treatment complexities require continuous monitoring and advanced solutions. Without proper management, these challenges can lead to higher operational costs, equipment failures, regulatory fines, and environmental risks.

- High Water Demand: Mining operations consume large amounts of water, making conservation and recycling essential for sustainability.

- Complex Treatment Processes: Removing heavy metals, suspended solids, and chemical residues requires advanced filtration and chemical treatments.

- Equipment Wear and Tear: Pumps, pipelines, and filtration systems face constant exposure to contaminants, leading to frequent maintenance and potential failures.

- Manual Testing Limitations: Traditional water sampling is time-consuming, prone to human error, and delays corrective actions.

Inefficient water management increases costs, disrupts operations, and exposes mining companies to compliance risks. Adopting automated water monitoring solutions enhances efficiency, reduces risks, and ensures sustainable operations.

How Automation Enhances Water Operations in Mining

Automated water monitoring is transforming mining operations by improving efficiency, accuracy, and compliance. Traditional water management relies on manual testing, which is time-consuming and prone to human error. Automation eliminates these inefficiencies, allowing for real-time monitoring and predictive insights.

- Real-Time Data Collection: Continuously tracks water quality and provides instant alerts for anomalies.

- Remote Access: Cloud-based platforms enable operators to monitor water conditions from any location.

- Predictive Analytics: AI-powered insights help detect trends and prevent contamination before it occurs.

- Regulatory Compliance Assurance: Automated reporting simplifies compliance and reduces the risk of violations.

Eliminating manual inefficiencies improves decision-making, reduces operational costs, and ensures better water quality management in mining.

Optimizing Mining Water Operations with Smart Technology

IoT-based water monitoring helps mining companies reduce risks, improve efficiency, and ensure compliance. Traditional water management methods rely on manual testing, which is slow and resource-intensive. Smart technology automates monitoring, enabling real-time data collection and proactive decision-making.

Automation lowers operational costs by reducing manual sampling and optimizing chemical use, ensuring precise water treatment while minimizing waste. It also enables a faster response to contamination, with instant alerts allowing operators to take immediate corrective action.

Smart monitoring enhances water recycling by improving filtration and reuse efficiency, reducing consumption, and minimizing environmental impact. Continuous monitoring of recycled water allows operators to detect quality fluctuations in real-time, ensuring compliance and optimizing treatment processes. By integrating automated solutions, mining companies can operate more sustainably while meeting regulatory standards.

How KETOS Revolutionizes Water Management in Mining

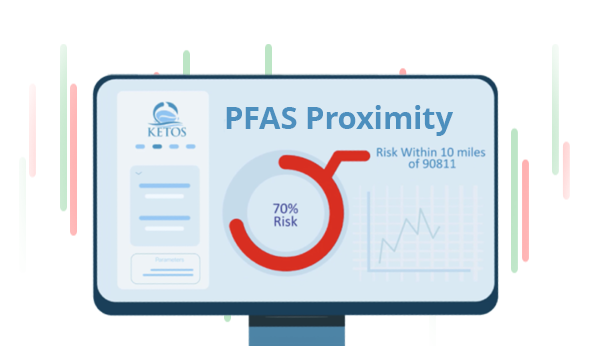

KETOS delivers advanced automated water monitoring solutions designed for mining and industrial applications. The KETOS Smart Water Intelligence Platform enables real-time water quality monitoring, predictive maintenance, and seamless integration with SCADA systems and cloud networks.

The KETOS SHIELD and KETOS WAVE platforms provide fully automated, real-time monitoring, eliminating the need for costly manual testing. Mining companies using KETOS can reduce costs, improve sustainability, and maintain compliance with minimal effort.

Upgrade your water management with smarter solutions. Contact us today to request a demo.