Water management is central to every mining operation. From ore processing to site rehabilitation, water must be treated, reused, or discharged according to strict environmental and safety guidelines. Hiring a qualified water operator ensures that operations remain efficient, compliant, and environmentally responsible.

What is the Role of a Water Operator?

A water operator in mining is responsible for managing and monitoring all aspects of water use at a mining site. Their job typically includes operating and maintaining water treatment systems, ensuring water quality, and documenting compliance with local and federal regulations. These professionals are often required to monitor influent and effluent flows, operate filtration and chemical treatment systems, and troubleshoot issues with pumps, valves, and automated controls.

The specific responsibilities of a water operator may differ depending on the type of mining operation, such as open-pit, underground, or placer mining. However, the core focus of the position remains the same. Water operators are essential for maintaining water quality, ensuring equipment functionality, and supporting site-wide safety and environmental compliance.

Water Operator Job Description in Mining Sites

Water operators in mining are responsible for running complex systems that manage how water is used, treated, and discharged. These duties go beyond basic maintenance. Operators must keep everything running smoothly, respond quickly to system changes, and document each step to meet strict environmental regulations.

Here is a general overview of what is included in a typical water operator job description within a mining context:

- Operate and maintain water and wastewater treatment systems.

- Monitor flow rates, pH levels, turbidity, and other key parameters.

- Perform routine inspections on pumps, valves, meters, and filtration units.

- Adjust chemical dosages and perform calibration of dosing equipment.

- Respond to alarms and troubleshoot mechanical or electrical issues.

- Collect samples and conduct field tests as required by permits.

- Maintain records of operational data and prepare reports for audits or inspections.

In remote or high-risk locations, operators may also be required to monitor emergency bypass systems and report on water volumes affected by rainfall or groundwater intrusion.

Core Qualifications to Look For

Hiring a water operator without the proper qualifications can expose a mine to regulatory violations and costly downtime. Before finalizing any employment offer, consider whether the applicant meets these minimum criteria:

| Qualification | Details |

| Certification | State-issued water treatment or wastewater operator certification (Class I-IV, depending on complexity) |

| Experience | 2–5 years operating water systems in industrial or remote environments |

| Technical Knowledge | Understanding of SCADA systems, pumps, membranes, and filtration |

| Physical Ability | Ability to lift 50+ lbs, climb stairs, and work outdoors in harsh conditions |

| Soft Skills | Attention to detail, teamwork, communication, and documentation accuracy |

Some mining operations also require water operators to have a valid driver’s license and the ability to work shift rotations or extended schedules on remote sites.

Compliance and Regulatory Expectations

Water discharge from mining operations is tightly regulated. Regulatory frameworks such as the Clean Water Act, the National Pollutant Discharge Elimination System (NPDES), and regional water board rules require regular reporting and precise tracking of contaminants, flows, and chemical usage.

A well-qualified water operator should be familiar with:

- Sampling procedures and lab coordination

- Documentation required for EPA and state audits

- Handling of hazardous materials and spills

- Emergency response procedures

- Permit-by-rule (PBR) conditions for site discharges

Failing to meet reporting or discharge criteria can halt operations or trigger fines. Therefore, technical ability must be paired with a thorough understanding of compliance standards.

Technology and System Familiarity

Modern mining sites use advanced water treatment technologies. Operators must often interact with programmable logic controllers (PLCs), remote monitoring systems, and digital water quality sensors. A basic understanding of how to navigate SCADA platforms or cloud-based water quality reporting tools is highly preferred.

Hiring water operators who are comfortable using both manual field tools and digital dashboards reduces onboarding time and ensures better system optimization across multiple shifts or remote facilities.

Key Performance Indicators for Water Operators

During hiring and performance reviews, mining operators should use KPIs to ensure the effectiveness of the water operator. Examples include:

- Consistent achievement of discharge permit limits.

- Reduced chemical usage through optimization.

- Minimal downtime of treatment systems.

- Accurate and timely reporting for all water sampling.

- Number of corrective maintenance issues identified and resolved.

Tracking these indicators helps companies tie operational efficiency and environmental compliance directly to employee performance.

Cost Considerations and Long-Term Value

Hiring a water operator isn’t just about hourly wages. Total costs can include relocation packages, training, PPE, and certification renewals. However, the return on investment is seen through consistent permit compliance, lower risk of fines, and improved efficiency in water treatment operations.

It’s also important to consider workforce stability. High turnover leads to knowledge gaps, safety risks, and greater maintenance needs. Retaining certified, experienced operators can create long-term savings and increase operational confidence.

Recruitment Challenges in Mining Regions

Many mining sites are located in remote or environmentally harsh regions. This can make recruiting certified water operators difficult. Companies may need to offer relocation assistance, sign-on bonuses, or flexible rotational shifts to attract talent.

Additionally, partnerships with technical schools or environmental training programs can help create a pipeline of future operators who are familiar with mining-specific needs and willing to work in field conditions.

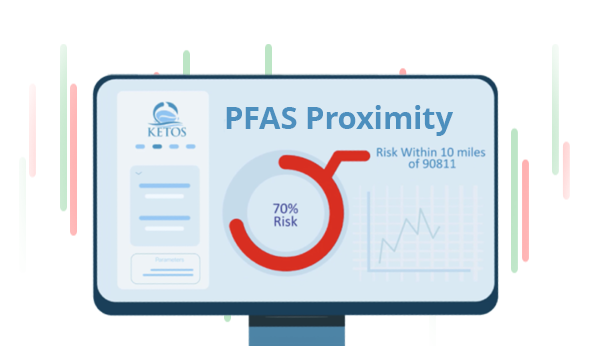

Supporting Performance with Real-Time Technology

Real-time data plays a growing role in mining water operations. Operators who can interpret alerts, troubleshoot based on analytics, and act quickly reduce the chances of overflow, contamination, or chemical overdosing.

This shift to real-time operations has redefined the expectations of the water operator. No longer is the job limited to routine sampling. Now, it includes understanding data trends, responding to predictive insights, and collaborating with digital platforms that control system parameters remotely.

How KETOS Supports Smarter Mining Operations

At KETOS, we help mining operations take control of water management with precision, automation, and real-time insight. Our fully integrated platform simplifies how water operators monitor, test, and report on water quality, reducing risk and improving efficiency across the entire site.

The KETOS SHIELD and WAVE systems are designed to:

- Monitor influent and effluent quality in real-time across dozens of critical parameters;

- Eliminate manual sampling through automated testing and reporting;

- Trigger threshold-based alerts before potential compliance issues escalate;

- Seamlessly integrate with SCADA systems and existing data platforms; and

- Apply predictive analytics to reduce chemical use, prevent failures, and optimize. operations

We offer 24/7 remote monitoring with no upfront capital costs. Our subscription-based model includes unlimited testing frequency, full platform access, and continuous support. This gives mining operators the tools to stay compliant, responsive, and cost-efficient.

Want to learn how we can help improve water operations at your mining site? Schedule a demo with KETOS today.