Water operators are vital to mining operations, managing water resources essential for extraction, processing, and waste management. Their expertise ensures operational efficiency, regulatory compliance, and environmental protection. By monitoring water quality, implementing treatment systems, and maintaining infrastructure, they address complex challenges like acid drainage and fluctuating water availability. As mining shifts toward sustainability, water operators play a key role in balancing production needs with environmental stewardship.

Water Source Management and Supply Systems

Managing water sources is a critical responsibility for water operators in mining. Their tasks include ensuring reliable supply, maintaining infrastructure, and monitoring water quality to prevent disruptions. Key responsibilities include:

- Source Monitoring: Collect and analyze samples to establish baseline parameters such as pH, turbidity, total dissolved solids, conductivity, and hardness. Use these benchmarks to detect changes or contamination risks.

- Infrastructure Maintenance: Inspect, repair, and maintain pumps, pipelines, storage tanks, and transport systems. Implement preventive maintenance schedules to avoid failures.

- Water Usage Tracking: Monitor consumption across operational areas, identify efficiency improvements, and ensure compliance with permitted extraction limits.

- Conservation Measures: During water scarcity, prioritize allocation for essential operations and implement strategies to minimize environmental impacts.

This systematic approach ensures a steady water supply while supporting operational efficiency and sustainability goals.

Water Quality Monitoring Programs

Effective water quality monitoring is essential for managing mining operations, ensuring compliance, and preventing regulatory issues. Mining companies rely on advanced water monitoring solutions to track key parameters across the water cycle, mitigating contamination risks and optimizing treatment processes. This requires a structured approach, including:

- Sampling: Regularly collect samples from process water, treated water, stored water, and discharge points. Use proper techniques to ensure accuracy and maintain chain-of-custody documentation.

- Parameters Monitored: Measure pH, turbidity, total dissolved solids, conductivity, and metal concentrations to detect changes or contamination risks.

- Data Analysis: Compare results against baseline data, regulatory thresholds, and operational standards. Field testing equipment enables immediate responses to anomalies.

- Recordkeeping: Maintain detailed logs of sample locations, methods, results, and observations. Use trend analysis to identify gradual changes and adjust treatment processes as needed.

- Continuous Monitoring: Leverage real-time monitoring systems for critical parameters to provide early warnings of potential issues.

Mining Water Treatment Operations

Water treatment is one of the most complex and critical responsibilities of water operators in mining. Advanced technologies, including IoT-driven wastewater treatment solutions , are transforming how contaminated water is treated for reuse or safe discharge while ensuring compliance with stringent environmental regulations. Below are the key aspects of mining water treatment operations:

| Aspect | Description |

| Types of Water Treated | Acid mine drainage, process water with reagents and dissolved metals, stormwater runoff from disturbed areas, general wastewater from support facilities. |

| Treatment Processes | Chemical (neutralization, precipitation, coagulation, flocculation, disinfection), physical (filtration, sedimentation), biological (natural or engineered systems for contaminant removal). |

| Operational Monitoring | Track flow rates, retention times, chemical dosing rates, and filtration performance. Adjust settings based on influent water quality and operational needs. |

| Chemical Management | Select appropriate chemicals, calculate dosage rates, calibrate dosing equipment, and ensure safe storage and documentation. |

| Equipment Maintenance | Inspect, repair, and maintain pumps, filters, membranes, and other treatment systems. Document performance and maintenance activities to identify recurring issues. |

| Optimization Opportunities | Conduct regular performance testing to improve treatment efficiency and reduce costs. |

This structured approach enables mining operations to meet stringent environmental regulations while maintaining operational efficiency and minimizing their environmental footprint.

Regulatory Compliance and Documentation

Key industry regulations are critical to ensure mining operations meet water management standards and environmental requirements. Proper licensing and certification requirements, such as those outlined by state regulatory agencies, further reinforce the need for qualified professionals in the field. Water operators are responsible for monitoring, reporting, and maintaining adherence to discharge permits and water quality standards.

Maintaining an accurate water balance is also essential for regulatory compliance. By tracking water inputs, consumption, and discharge, mining operations can ensure they remain within permitted usage limits and prevent unaccounted water losses that could lead to compliance issues. The following key aspects outline how water operators manage compliance and documentation effectively:

| Aspect | Description |

| Discharge Monitoring | Collect samples per permit requirements and verify compliance before release. |

| Documentation | Maintain records of monitoring, treatment, and discharge activities; track water balance data to ensure sustainable resource use. |

| Permit Management | Track permit requirements, renewal dates, and water consumption limits to meet environmental regulations. |

| Compliance Strategies | Implement water tracking systems to account for inputs (precipitation, groundwater inflow, surface withdrawals) and losses (evaporation, cooling, storage of materials, and dust control) |

Emergency Preparedness and Response

Mining water operators play a critical role in safeguarding water systems by planning, monitoring, and responding to emergencies. Their key responsibilities include:

- Emergency Planning: Develop response plans for extreme weather, equipment failures, pipeline breaks, and power outages, ensuring clear roles and communication protocols.

- Weather Preparedness: Adjust water management strategies based on forecasts to mitigate risks from heavy rainfall, droughts, or freezing conditions.

- Equipment Contingency: Establish backup systems, alternative treatment methods, and vendor support contacts for rapid repairs.

- Incident Assessment: Document emergency impacts, response actions, and preventive measures to strengthen future preparedness.

- Regulatory Compliance: Align emergency plans with Mine Emergency Response Plans (MERPs) and update them regularly to address emerging risks.

A structured approach ensures mining operations remain resilient while minimizing disruptions to water systems.

Water Conservation and Reuse Strategies

Water operators play a pivotal role in reducing freshwater consumption and promoting sustainability in mining operations. By leveraging integrated water management strategies, they can optimize resource use, enhance efficiency, and minimize environmental impact. Their strategies focus on recycling, stormwater reuse, and improving water efficiency while lowering operational costs.

- Process Water Recycling: Design systems to capture and treat water from operational areas for reuse. Monitor quality to ensure it meets specifications, significantly reducing freshwater withdrawals.

- Stormwater Management: Segregate clean runoff from undisturbed areas for operational use, while treating contact water from mining areas before reuse or discharge.

- Water Efficiency Improvements: Collaborate with process teams to implement water-saving measures, monitor usage metrics (e.g., gallons per ton processed), and audit systems to identify leaks or inefficiencies.

- Advanced Technologies: Incorporate closed-loop systems, predictive analytics, and decentralized treatment solutions to minimize freshwater use and optimize water management.

These conservation efforts not only reduce environmental impacts but also enhance operational efficiency, ensuring sustainable water use throughout the mining lifecycle.

Technology Integration for Water Management

Advanced technologies are transforming water management in mining, enhancing monitoring, treatment, and decision-making while reducing costs and environmental risks. Implementing smart water management strategies enables mining operations to optimize resource use and improve sustainability.

- Automated Monitoring Systems: Sensors measure parameters like flow rates, pH, conductivity, and turbidity in real-time, transmitting data to centralized platforms for trend analysis and anomaly alerts.

- Remote Control Capabilities: Automated valves, variable-speed pumps, and programmable controllers allow operators to adjust system parameters efficiently, even from off-site locations.

- Data Management Tools: Software aggregates data from multiple sources, applies analytics, and generates actionable insights to optimize operations and ensure compliance.

- AI and IoT Integration: AI-driven systems predict water quality changes and optimize asset performance, while IoT sensors provide real-time data for smarter water management decisions.

- Innovative Treatment Solutions: Technologies like dry disposal, coarser particle filtration, and seawater desalination reduce freshwater use and improve wastewater recycling efficiency.

The integration of these technologies allows mining operations to enhance water management sustainability, boost operational efficiency, and ensure regulatory compliance.

Mining Water Operator Certification & Training

Certification plays an essential role in ensuring that water operators possess the necessary expertise to manage resources effectively. Industry standards emphasize proper training in areas such as treatment processes, regulatory compliance, and monitoring techniques, aligning with established certification requirements for water operators.

Key skills and training areas include:

- Math and analytical skills for water flow calculations.

- Mechanical aptitude for maintaining treatment systems.

- Chemical knowledge for water quality control.

- Compliance awareness for mining regulations.

- Troubleshooting for system efficiency.

Common training programs cover:

- Mine Water Treatment & Management

- Environmental Compliance & Water Regulations

- Advanced Water Monitoring Technologies

- Equipment Maintenance & Operations

Operators often obtain liscensing as a Certified Water Operator (CWO) or Mine Water Treatment Specialist, and can earn Environmental Water Compliance Certification to meet industry regulations.

Career Path & Job Opportunities in Mining Water Management

As mining water operations become more advanced, professionals must meet evolving industry expectations and regulatory standards. Many roles, from entry-level technicians to senior compliance specialists, require knowledge and skills that align with competency criteria for certified water operators, ensuring consistency across the industry.

Career progression opportunities include:

- Entry-Level Roles: Water Treatment Plant Technician, Water Sampling & Analysis Technician

- Mid-Level Roles: Senior Water Operator, Mine Water Quality Analyst

- Advanced Roles: Mining Water Resource Manager, Environmental Compliance Director

With automation and sustainability initiatives shaping the industry, certified water operators are in high demand, making continuous learning essential for career growth.

Smart Water Solutions for Mining Operations

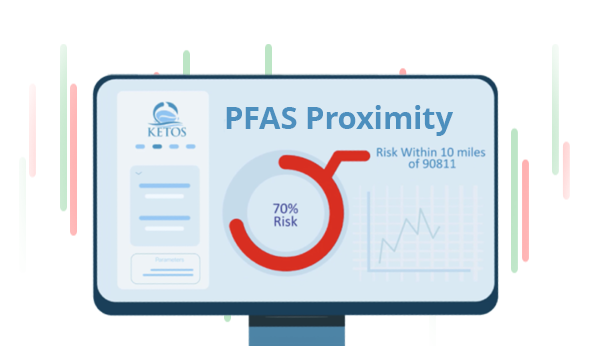

KETOS provides mining companies with advanced water management solutions designed to optimize efficiency, ensure compliance, and support sustainability. By leveraging real-time monitoring, predictive analytics, and automated reporting, KETOS empowers water operators to address critical challenges with precision and ease. Key benefits include:

- Access lab-accurate data on key parameters like pH, turbidity, and heavy metals for continuous oversight.

- AI-driven insights help forecast water quality changes and optimize treatment processes.

- Threshold-based alerts and compliance-ready documentation streamline operations and reduce manual effort.

- Optimize water recycling and reuse to minimize environmental impact and freshwater consumption.

Discover how KETOS can transform your water management practices. Contact us or request a demo to explore our innovative solutions tailored to mining operations.