Learn How Automated Water Sampling Saves Cities & Businesses Hundreds of Hours Each Year…

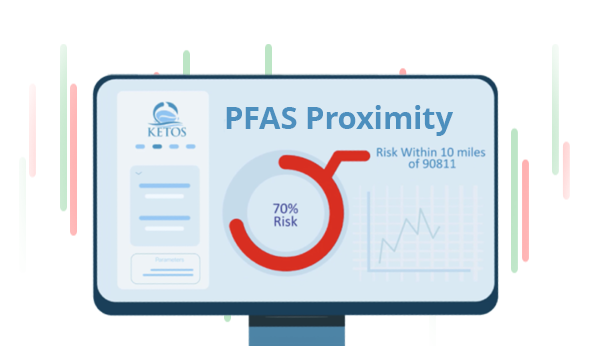

PFAS Exposure In the USA

WEBINAR: Operational Value of Water Quality Intelligence in Agriculture

Oct 23, 2024 at 11:00 AM EST

Beverage companies rely on water quality to deliver premium products that taste great across every batch. Autonomously monitor water quality with KETOS to test over 30 parameters while also maintaining compliance and regulatory standards.

Understand your water composition so that your final product output becomes more predictable, with fewer wasted batches.

Capture real-time data related to filter performance and leverage KETOS machine learning to prescribe when filters should be replaced.

Our results are delivered in real-time and with lab accuracy, giving you the peace of mind of knowing the readings you get are timely and precise.

With water composition continuously monitored, you can avoid spikes or delays in action for more predictable quality and taste.

Reduce time and expense associated with manual labor and outsourcing of sample collection and lab testing.

KETOS monitors for nutrients, environmental factors (pH, ORP, alkalinity, etc.), heavy metals (lead, arsenic), and inorganics.

When beverage companies draw from water sources, they need to deal with compliance and quality control. Read how KETOS was able to help one brewing company with a full lifecycle remediation process and how they were able to automate water quality testing for a more streamlined approach to monitoring.

Beverage companies must monitor water quality to ensure product quality and taste consistency across batches. They also may require active monitoring to ensure that the water they pull from – specifically groundwater – complies with local regulations.

Some organizations may pull their water supplies from multiple sources, including municipal and groundwater supplies, which would require quality monitoring. The result is a multifaceted approach to sampling, with different areas potentially requiring monitoring simultaneously. Manual labor on-site is needed to pull the requisite samples, coupled with third-party lab costs can begin to get expensive. However, with automation, beverage companies not only get a better understanding of their water quality but can also lower costs.

Using KETOS, water samples can be pulled from multiple sources at once for complete lifecycle monitoring. Automation can help beverage companies know when filters need replacing and the level of filter performance to ensure consistent quality and taste. Automation also allows them to act fast if there are spikes in specific parameters, ensuring they stay compliant with local regulatory bodies.

With KETOS, beverage companies:

While water operators get a better understanding of the water quality at every step of the production process, companies spend just pennies on the dollar for automated testing and state-of-the-art devices installed into existing infrastructure without high upfront costs.

"*" indicates required fields

Subscribe to our newsletter to stay updated with the latest water insights.

"*" indicates required fields

Copyright © All rights reserved.

Website & Graphic Design by MediumInteractive.com