Mining operations demand precise water management due to the environmental, regulatory, and operational requirements of extracting and processing raw materials. Whether it’s dewatering, treatment, or monitoring discharge quality, hiring a qualified water operator is critical to the success and sustainability of mining water operations. Understanding what to look for in a candidate ensures that your site remains compliant, efficient, and environmentally responsible.

Understanding the Role of a Mining Water Operator

A mining water operator’s role includes managing and maintaining systems that treat and move water used or produced during mining activities. These systems often include filtration units, reverse osmosis systems, chemical treatment processes, and wastewater discharge infrastructure. Operators ensure that water quality meets regulatory standards while optimizing operational performance to reduce costs and environmental impact.

They may also handle routine water sampling, data collection, troubleshooting equipment issues, and reporting results to regulatory bodies. In modern operations, digital monitoring systems and automated platforms are becoming essential tools, and operators must adapt to these technologies as part of their day-to-day activities.

Key Water Operator Skills to Evaluate

Hiring a water operator for a mining environment requires assessing technical competencies, experience with mining processes, and familiarity with water quality regulations. Focus on candidates who possess the following:

- Knowledge of water chemistry and the treatment methods used for removing solids, metals, and contaminants.

- Operational experience with pumps, tanks, filters, dosing systems, and monitoring devices.

- Data logging and interpretation skills for generating accurate compliance reports.

- Proficiency with digital systems like SCADA, IoT-based monitoring, and predictive analytics tools.

- Emergency response preparedness for handling spills, overflows, or system failures.

- Understanding of OSHA safety standards and site-specific health protocols.

Operators with practical experience in the mining industry will typically have better insight into water-use challenges related to tailings, dust suppression, heap leaching, and groundwater control.

Recognizing Water Operator Certification Requirements

Certifications validate a water operator’s competence and understanding of public health and environmental safety standards. These credentials are often mandatory, especially when operators oversee treatment systems that discharge into public waterways or sensitive ecosystems.

| Certification | Description | Issuing Authority |

| Class I–IV Water Operator Certification | Tiered levels based on system complexity and experience | State Environmental or Health Departments |

| Wastewater Treatment Operator License | Required for managing effluent treatment and discharge | State Agencies, often under EPA guidelines |

| Confined Space Entry and Safety Training | Mandatory for operators working in tanks, pits, or underground | OSHA-certified training providers |

| SCADA or Digital Water Monitoring Certification | Relevant for operations using automated platforms and remote sensing | Technical Training Institutes or Equipment Manufacturers |

Certification requirements may vary depending on the state, the size of the facility, and whether the operation falls under federal regulations. Employers should verify that candidates maintain up-to-date credentials and continuing education hours where required.

Mining Water Operations and Technology Integration

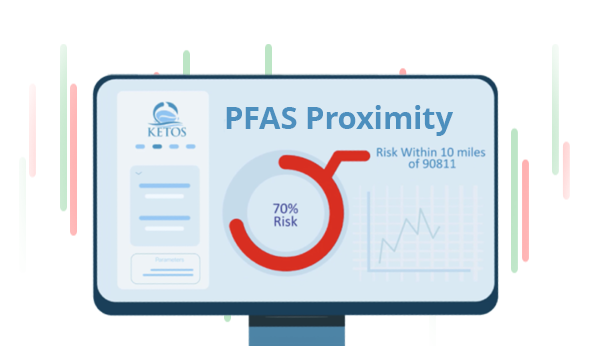

The complexity of mining water operations has significantly increased with the need for more data-driven, automated, and compliant solutions. Many operations now rely on digital water intelligence platforms, predictive analytics, and real-time monitoring to maintain control and optimize system performance. It’s critical to hire a water operator who can confidently interact with these technologies and support a digitally managed water strategy.

Modern mining water management incorporates elements such as:

- Real-time data logging from multiple remote sensors.

- Automated water sampling and parameter testing.

- Threshold-based alerts for contaminants or flow irregularities.

- Integration with SCADA, ERP, and compliance databases.

- Predictive maintenance alerts and anomaly detection.

Candidates who are comfortable with cloud-based systems and IoT-enabled infrastructure bring additional value, especially when working with platforms that reduce the need for manual sampling and improve reporting accuracy.

Interviewing Strategies for Hiring a Water Operator

During the hiring process, structure your interviews to uncover both technical knowledge and practical experience. Use scenario-based questions that reflect real challenges encountered in mining environments. Sample questions may include:

- “How would you respond to a rising pH level in the final discharge tank?”

- “What steps do you take when a flow meter begins reporting irregular data?”

- “Describe your experience with automated water monitoring systems.”

- “How have you handled equipment failures in remote locations?”

- “What methods do you use for troubleshooting water imbalances?”

Also, ask candidates to walk through their understanding of water treatment chemistry, their routine sampling protocols, and any digital reporting tools they’ve used. Prioritize those with hands-on experience in environments that mirror your operation’s scale and complexity.

Regulatory Considerations and Compliance Awareness

Mining water operations are subject to strict local, state, and federal regulations. Discharge permits, groundwater protection rules, and heavy metal limitations must be monitored continuously. Hiring a water operator who is aware of these regulations—and who understands how to maintain documentation and operate within these limits—is essential to preventing fines, environmental violations, or production delays.

Key compliance areas include:

- National Pollutant Discharge Elimination System (NPDES) permits.

- Groundwater monitoring and aquifer protection requirements.

- Heavy metal and nutrient discharge thresholds.

- Reporting formats and schedules for state agencies.

- Emergency discharge plans and risk assessments.

Candidates with a compliance-first mindset help safeguard operations while supporting long-term sustainability and stakeholder trust.

Evaluating Fit for Long-Term Operational Success

Water operators often serve as the backbone of mining site sustainability efforts. A strong hire can provide years of operational reliability, consistent data tracking, and insights that help refine water management strategies. Look for candidates who demonstrate problem-solving initiative, long-term commitment, and an ability to adapt to new technologies and environmental standards.

Other indicators of a good long-term fit include:

- Positive safety record with minimal violations or incidents.

- Demonstrated history of equipment care and preventative maintenance.

- Willingness to continue certifications and training.

- Ability to collaborate across environmental, engineering, and compliance teams.

- Strong communication skills for clear documentation and reporting.

Operational continuity, especially in remote or high-output mining locations, depends on hiring individuals who understand their value to the process and who can grow with the operation over time.

Streamlining Success with KETOS

As mining operations move toward fully integrated, real-time water monitoring, having the right tools in place is just as important as hiring the right people. That’s where KETOS comes in. By delivering an advanced platform that combines EPA-compliant sensor technology, predictive analytics, and zero-capex deployment, KETOS empowers water operators to manage their responsibilities more efficiently and accurately.

KETOS enables mining operations to:

- Automate testing across 30+ water quality parameters.

- Reduce labor hours and manual sampling costs.

- Access cloud-based reports and real-time alerts anytime, anywhere.

- Ensure compliance with evolving environmental regulations.

- Leverage predictive maintenance to avoid system failures.

With solutions like the KETOS SHIELD and KETOS WAVE, your water operators gain powerful tools that simplify complex tasks, allowing them to focus on quality, efficiency, and long-term sustainability. Whether you’re building a new team or upgrading your infrastructure, KETOS makes intelligent water management simple, scalable, and smart.

Ready to optimize your mining water operations? Contact us today to learn more or request a personalized demo and see how KETOS can support your team and compliance goals.