Learn How Automated Water Sampling Saves Cities & Businesses Hundreds of Hours Each Year…

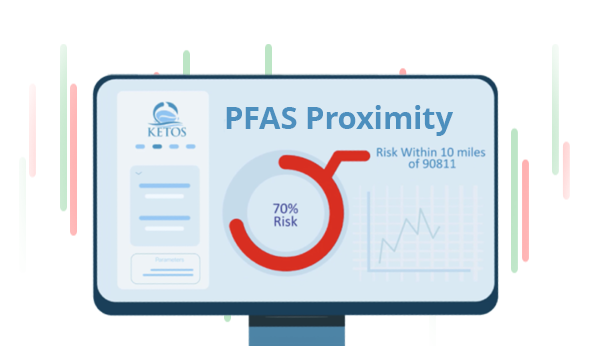

PFAS Exposure In the USA

WEBINAR: Operational Value of Water Quality Intelligence in Agriculture

Oct 23, 2024 at 11:00 AM EST

Pulp and paper operations grind to a halt when boilers face downtime. That’s why automation is critical. Having a water quality monitoring solution that can monitor boilers, process water, mill tanks, and more can ensure water quality.

Place KETOS hardware strategically in existing operations to monitor boilers, process water, mill tanks, etc., from one place.

Keep the infrastructure you have and make it better with KETOS. Our solution plugs right into your water systems and helps prevent data silos.

Test for 30+ parameters, including total hardness, orthophosphates, calcium, heavy metals (copper, iron, etc.), residual chlorine, and more.

Leverage automation for testing at regular intervals to better understand your organization’s usage and water quality.

Use less water in your operations, protect equipment, balance water chemicals, and recycle water more effectively.

Get an accurate real-time view of water quality for more streamlined operations and better overall water quality.

Pulp and paper operations rely on boiler uptime in order to be able to meet production goals. However, companies can face equipment issues and increased downtime without proper water quality management. Find out how one Fortune 500 company leveraged KETOS to monitor water in their mill tank, boiler, and process water to increase their rate of return by 15%, thanks to more predictable uptime.

Pulp and paper operations risk downtime when boilers must be taken offline for maintenance. Water treatment challenges can often impact the quality and consistency of boiler and process water, which can severely impact production capacity.

Automation of water quality, however, can help water operators in pulp and paper better monitor their water to ensure the optimal balance of chemicals. This protects equipment and reduces downtime, helping the organization provide for a more predictable production capacity month over month.

With KETOS, pulp and paper operations can:

KETOS provides automated testing that is lab-accurate and in real-time without the need for manual interventions or third-party testing that can delay analysis and action. With an added layer of machine learning and AI, operators are able to build insights into usage to help them better protect against equipment downtime while reducing water usage and labor costs.

"*" indicates required fields

Subscribe to our newsletter to stay updated with the latest water insights.

"*" indicates required fields

Copyright © All rights reserved.

Website & Graphic Design by MediumInteractive.com